50t induction furnace

Max load capacity . 60t

Rated power kw 26000

Working frequency Hz 150

Melting rate t/h 30-35

Power consumption kw.h/t 560-590

50T medium frequency steel shell induction melting furnace technical specification and complete set range

Ⅰ Technical program and specification

This program is recommended that whole set equipment of the furnace shall be equipped with two furnace bodies user can be readjusted by practical needs.

1.1 Technical program

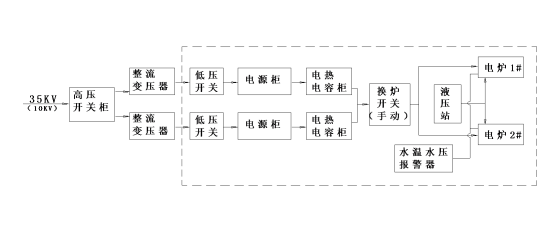

The main equipment of this program is included 2 13000KVA rectification

transformer, 4 low voltage control cabinet, 4 power supply cabinet, total power is 26000KW. 2 50t MF induction furnace, 1 hydraulic station (double motor double pump, type electromotion), 1 cooling water device, and other auxiliary device. The electric system diagram is as follows:

The output of MF power supply is changed by furnace-changing switch, for the purpose of maintenance and alternative melting.

1.2 Technical parameter

|

Name |

Unit |

Parameter |

Remark |

|||||

|

Rated capacity |

t |

50 |

|

|||||

|

Max load capacity |

t |

60 |

|

|||||

|

Rated power |

kw |

26000 |

|

|||||

|

Working frequency |

Hz |

150 |

|

|||||

|

Melting rate |

t/h |

30-35 |

1600℃ |

|||||

|

Power consumption |

kw.h/t |

560-590 |

1600℃ |

|||||

|

Inductor inner diameter |

mm |

Φ2220 |

|

|||||

|

Height of inductor |

mm |

3000 |

|

|||||

|

Rated temperature of the working |

℃ |

1600 |

|

|||||

|

Incoming voltage |

v |

1000 |

|

|||||

|

Incoming current |

A |

4050 |

|

|||||

|

Electric rectificate mode |

|

24 pulse |

|

|||||

|

Voltage of inductor |

V |

3400 |

Double voltage |

|||||

|

Cooling water of the furnace |

Pressure of incoming water |

Mpa |

0.25~0.3 |

|

||||

|

Temperature of incoming water |

℃ |

≤5~35 |

|

|||||

|

Temperature of outlet water |

℃ |

≤55 |

|

|||||

|

Flow rate ( furnace body) |

t/h |

460 |

Single furnace (230) |

|||||

|

Flow rate ( power source) |

t/h |

160 |

|

|||||

|

Water temperature rise of power source |

℃ |

10 |

|

|||||

|

Cooling water pressure for power source |

Mpa |

0.1~0.2 |

|

|||||

|

Hydraulic system |

Working pressure |

Mpa |

12 |

Doublemotor, double pump |

||||

|

Flow rate |

L/min |

190 |

|

|||||

|

Hydraulic medium |

|

Antiwear hydraulic oil

|

Summer:N68 Winter: N46 |

|||||

|

Diameter of the hydraulic cylinder |

mm |

Φ320 |

|

|||||

|

Capacity of the transformer |

KVA |

13000×2sets |

( Reference ) |

|||||

|

Primary voltage |

KV |

10 or 35 |

|

|||||

|

Secondary voltage |

V |

1000 |

|

|||||

|

Connection way |

|

Extension triangle phase shift ±7.5º namely:D(+7.5º)dyn D(-7.5º)dyn |

|

|||||

|

Impedance voltage |

|

8~9% |

|

|||||

|

Phase number |

|

3 phase input,6 phase output |

|

|||||

|

Pressure adjustment way |

|

No excitation |

|

|||||

|

Cooling way |

|

Strong grease |

|

|||||

Ⅱ Products standard and Operating conditions

2.1 Products standard:

GB10067.3-1988 ‘Basic specifications for electroheat installations--Induction electroheat installations’

GB10067.1-1988 ‘Basic specifications for electroheat installations—General’

GB10066.3-2004 ‘Test methods for electroheat installations--Coreless induction furnaces’

GB5959.1-2005 ‘Safety in electroheat installations-- General requirements’

GB5959.3-1988 ‘Safety in electroheat installations--Particular requirements for induction and conduction heating installations and induction melting installations’

2.2 Operating conditions

2.2.1 Cooling water conditions

PH:7-8.5

Hardness:<10 degrees(Each degree that 1L water contains less than 10mg calcium oxide)

Total solid content:<250mg/L

Water resistance:(Power)>100KΩ-cm

(Furnace)>2KΩ-cm

2.2.2 Power supply conditions

a. Three-phase voltage unbalancedness <5%

b. Voltage fluctuations <±5%

c. Voltage waveform distortion factor <10%

2.2.3 Geographical environment

a. Altitude above sea level <1000m

b. Temperature 5~40℃

c. Relative humidity <90%(>20℃)

d. No electric and incentive atomy, no Explosive Gas and no caustic gas

e. Avoid strong shake and concussion.

III 1 set of Medium Frequency Furnaces, Equipment list and supply range

|

No.

|

Description

|

Unit

|

Qty |

Single Wt (t) |

Total Wt (t) |

|

1 |

25T Medium-frequency Induction furnace |

set |

2 |

65 |

130 |

|

2 |

Low voltage power cabinet |

set |

4 |

2.5 |

10 |

|

3 |

Power cabinet |

set |

4 |

4.5 |

18 |

|

4 |

Compensate capacitor banks |

set |

2 |

7 |

14 |

|

5 |

Tilting hydraulic system |

set |

1 |

3 |

3 |

|

6 |

Hydraulic electric control cabinet |

set |

1 |

1 |

1 |

|

7 |

Furnace changing switch |

set |

1 |

0.5 |

0.5 |

|

8 |

Cooling water cable for furnace shell |

pc |

32 |

|

|

|

9 |

Connect cable from power cabinet to capacitor cabinet |

pc |

8 |

|

|

|

10 |

Connect cable from capacitor cabinet to Furnace changing switch |

pc |

12 |

|

|

|

11 |

Crucible mould |

pc |

1 |

|

|

|

12 |

Hydraulic pipeΦ28 (including connector) |

pc |

1 |

|

|

|

13 |

Temperature /pressure alarm system |

set |

1 |

|

|

|

14 |

Technical data |

copy |

1 |

|

|

|

|

Total price (USD) |

|

|||

IV Medium frequency furnaces randomness replacement parts:

1) KP 1piece、KK 1piece

2) Rectification expander board 1piece

3) Vary inversely expander board 1piece

4) Primary control program plate 1piece

5) DC electric pressure gage 1piece、DC electric current gage 1piece、coil in electric current gage 1piece、MF electric current gage 1piece、frequency table 1piece.

Annotation:This equipment hydraulic system adoption double motor double pump (one work one reservation), union take explosion proof valve.

V. Payment way:

30% advance payment, 70% payment paid before date of shipment or by L/C (opening bank need international famous bank)

VI. Management Installation :

Totally oversea charges paid by buyer. The buyer shall compensate the experts at USD 150 per day for delaying time per engineer. The seller should be responsible for the scene testing; After normal melting the seller should be responsible to guarantee repair or change of the faulty components in 6 months